- Home

- About us

- Products

- PE air bubble film machine

- Stretch film machine

- Film Blowing Machine

- Printing Machine

- Bag Making Machine

- Plastic Recycle Machine

- Plastic Film Slitting and Rewinder Machine

- Plastic Rope Making Machine

- Plastic Glove Making Machine

- Paper bag making machine

- Air column bag making machine

- Paper Straw Machine

- Faqs

- News

- Certificate

- Contact us

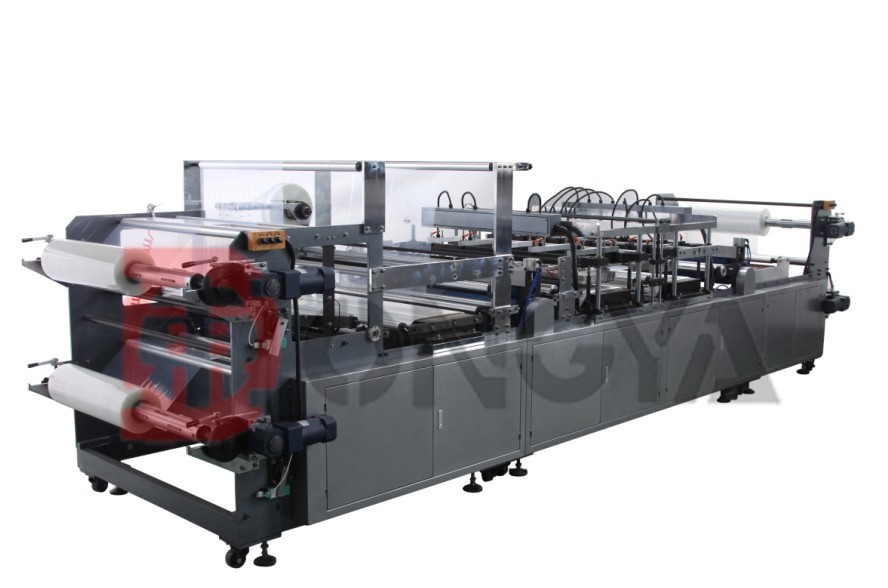

buffer column manufacturing machine

- FOB Price

US $40000.001 - 5 piece

- group name

- Air column bag making machine

- Min Order

- 1 piece

- brand name

- Vinot

- model

- DY-1200

- Nearest port for product export

- Ningbo, Shanghai

- Acceptable payment methods

- T/T, L/C, Westem Union, Cash

- update time

- Wed, 01 Nov 2017 16:40:55 GMT

Packging & Delivery

- 500cm x 180cm x 160cm

-

Min Order1 piece

Briefing

Detailed

Model : DY-1200 (roll type)

Model : DY-1200 (roll type)

Technical Parameters:

Membrane Roll Size | Max. roll width: 1250mm |

Max. roll diameter | 500mm |

The Highest Speed of Column Pressing: 18 cycles/min.(Speed adjustable)

| 20 mm column- 14 columns per pressing |

30 mm column- 10 columns per pressing

| |

40 mm column- 7 columns per pressing

| |

60 mm column- 5 columns per pressing

| |

The Max. Width of Pressed Column:

| 1220mm |

Power consumption:

| 15.2 kw |

Air supply:

| 0.68MPA |

Weight:

| 2800kg |

Dimensions:

| 5320 X 1800 X 1680 mm |

Column Pressing Parameters: Realized via PLC control panel for column pressing speed, welding temperature, pressing time, standards compensation,etc.

DY-1200 (roll type) ,this machine should be combined with DY-800 (bag piece by piece),both sets of equipment together through certain procedures to the products of raw material into a cushioning packaging material roll film.

Model : DY-800 ( bag piece by piece)

Technical Parameters:

Membrane Roll Size: Max. roll width:

| 1250mm |

Max. roll diameter:

| 500mm |

The Highest Speed of Column Pressing: 18 cycles/min.(Speed adjustable)

| 20 mm column- 14 columns per pressing

|

30 mm column- 10 columns per pressing

| |

40 mm column- 7 columns per pressing

| |

60 mm column- 5 columns per pressing

| |

The Max. Width of Pressed Column:

| 1220mm |

Power consumption:

| 15.2 kw

|

Air supply: | 0.68MPA |

Weight:

| 2800kg |

Dimensions:

| 5320 X 1800 X 1680 mm |

This production line uses PE/PA co-extruded film and the air valve film to weld air column sheet first, then fold the air column sheet to the desired bag pattern, and then sealand cut to get the finished air column bags. Wide range of bag patterns can beachieved by this line such as Q bag, U bag, Cap, Pad, etc., for differentcushion packaging requirement. Promivision fully automatic high speed aircolumn bag production line boasts high efficiency, versatility and flexibility.

Realized by PCL control panel for setting pressing time, pressing temperature, standards compensation, roll-unwinding,automatic variation correction system.