- Home

- About us

- Products

- PE air bubble film machine

- Stretch film machine

- Film Blowing Machine

- Printing Machine

- Bag Making Machine

- Plastic Recycle Machine

- Plastic Film Slitting and Rewinder Machine

- Plastic Rope Making Machine

- Plastic Glove Making Machine

- Paper bag making machine

- Air column bag making machine

- Paper Straw Machine

- Faqs

- News

- Certificate

- Contact us

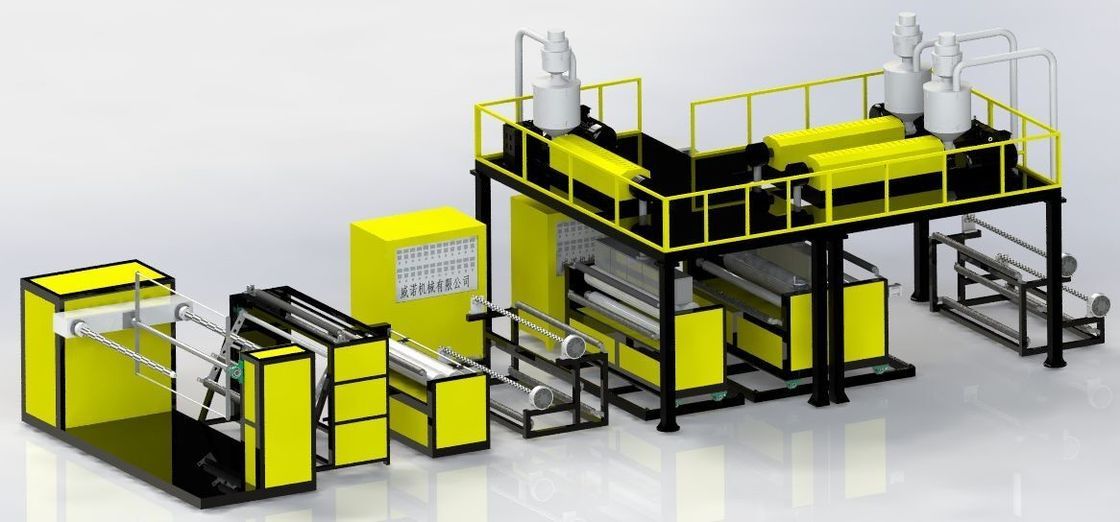

50 - 150kg / H Output Bubble Wrap Manufacturing Machine Safe Design

- group name

- PE air bubble film machine

- Min Order

- 1 piece

- brand name

- Vinot

- model

- DY-1600/DY-1800/DY-2000/DY-2200/DY-2500

- Nearest port for product export

- Ningbo, Shanghai

- Acceptable payment methods

- T/T, L/C, Westem Union, Cash

- update time

- Fri, 12 Jan 2018 08:45:01 GMT

Packging & Delivery

-

Min Order1 piece

Briefing

Detailed

50 - 150kg / H Output Bubble Wrap Manufacturing Machine Safe Design

| L / D Ratio: | 30 : 1 | Film Width: | 1200 - 2000mm |

|---|---|---|---|

| Output: | 50 - 150kg / H | Screw Diameter: | 50 - 65mm / 55 - 70mm / 65 - 90mm |

| Bubble Specification: | 6 X 3.2mm 10 X 3.8mm 25 X10 Mm 30 X 10mm | Material: | HDPE / LDPE |

Ⅰ. Characteristic

♦ Bubble Wrap Machine adopts once-through shaping technique, thus has high efficiency and excellent product quality.

♦ Bubble Wrap Machine set has such features as scientific and reasonable structure design, smooth and reliable running and convenient operation and maintenance.

♦ Polyethylene air-cushion film (also called polyethylene bubble film), which is divided into two kind: ordinary polyethylene air-cushion film and composite polyethylene air-cushion film, is a kind of packing material which has been widely used at present.

♦ It not only has good cushioning effect, shock resistance and heat-sealing performance, but also has such advantages as good corrosion resistance and transparency , etc.

♦ So it has been widely used for packing, household wares, post parcel, bicycle , polyurethane furniture, etc.

Ⅱ. Feature

This air crew adopts the disposable shaping craft.It is our factory that draws domestic and international advanced technology extensively, through a large number of production practices in having ordinary equipment originally, develop, design, can produced polyethylene compound bubble (cushion) membrane in succession. Designs science, practical. Rational in structure of the machine.

Bubble Wrap Machine is made of LDPE material. It can be used for various packaging purposes such as moisture proving, dust proving, shock proving, and static prevention. It can also make into laminated films with aluminized film, foamed PE sheet, and paper are the applications of sun shading, heat insulation, and packaging.

Main Specification:

| Model | DYF-1600 |

| Main and auxiliary extruder screw diameter | Φ70mm Φ55mm |

| L/D | 30:1 |

| Main and auxiliary extruder electrical power | 18.5KW 11KW |

| Width of production | 1600 mm |

| Main bubble specification | 10×3.8mm 6×3.2mm 25×10mm 30×10mm |

| Output | 60-110kg/h |

| Total installed capacity | 98kw |

| Overall dimension | 7500mm×2800mm×2800mm |

| Gross weight | 6.8T |

Packaging & Shipping

- Port: Ningbo

- Packaging details: With stretch film and bubble film package outside

- Delivery detail: Within 30 work days after receiving the deposit payment